Heat Pump Troubleshooting Tips for Greensboro, Jamestown & High Point

Heat pumps move heat instead of creating it, which makes them one of the most efficient ways to heat and cool properties around Greensboro, NC and nearby towns. This guide walks you through the most common problems, explains how the main components work, and gives clear, safe steps you can take before calling a pro. You’ll learn why a heat pump might stop heating, what causes frost build-up or short cycling, why a unit can blow cold air in heat mode, and which routine tasks help avoid breakdowns. We include local context for Greensboro, Jamestown, and High Point weather patterns, plus straightforward DIY checks, quick symptom lists, and simple rules for when to schedule service. Read on for step-by-step troubleshooting and practical next steps to restore comfort and efficiency.

Why Isn’t My Heat Pump Heating? Common Causes and What to Try First in Greensboro

When a heat pump isn’t producing heat, it usually means one of the system’s key functions isn’t moving heat correctly — common culprits are thermostat settings, low refrigerant, or electrical problems that stop the compressor. These issues reduce output and raise energy bills, often showing as weak airflow, longer run times, or ice on the outdoor coil. Many simple problems can be ruled out with a few homeowner checks; refrigerant leaks and compressor failures require certified diagnostics to avoid further damage. Use the checklist and quick comparison below to decide whether you can safely troubleshoot or should call a technician.

Quick homeowner checks before you call a technician:

- Confirm the thermostat is set to heat and the temperature setpoint is higher than the room temperature.

- Check the indoor air filter and replace it if it’s dirty — clogged filters cut airflow and performance.

- Verify power at the breaker and the outdoor unit; only reset a tripped breaker if it’s safe and obvious.

- Look at the outdoor unit for loud or unusual noises, visible ice, or oil stains, which point to refrigerant or defrost problems.

These basic checks often clear up simple issues like mis-settings or restricted airflow and help you identify when component-level testing is needed.

The table below matches likely causes with common symptoms and suggested next steps for “no heat” scenarios.

| Likely Cause | Typical Symptom | Recommended Next Step |

|---|---|---|

| Thermostat misconfiguration | System is off or cycles incorrectly | Confirm mode, replace batteries, check schedule; reset if needed |

| Low refrigerant / leak | Weak heat, hissing sounds, ice on outdoor coil | Do not attempt recharging; schedule professional leak detection |

| Electrical or breaker fault | No power to outdoor unit; compressor won’t run | Inspect breakers and switches, then call a licensed electrician if problem continues |

| Compressor or contactor failure | Clicking sounds, short runs, no sustained heat | Stop extended use and arrange technician testing |

Use these cause-to-symptom pairings to limit DIY work to safe tasks and avoid handling refrigerant or live electrical components yourself.

What Thermostat Issues Can Prevent Heating?

Thermostat problems often look like a system failure even when the heat pump is otherwise fine. Common issues include the thermostat being set to “cool,” active auto schedules that override manual settings, weak batteries, or loss of communication with a smart thermostat. Start by confirming the display shows heat mode, replace batteries if present, and temporarily set a manual heating temperature to see if the system responds. If settings don’t stick or wiring looks loose, the thermostat or its wiring may need a professional check to avoid damaging controls.

These thermostat checks are quick and free and will point you toward airflow or refrigerant checks if heating still doesn’t occur.

How Does Low Refrigerant Affect Performance?

Low refrigerant reduces the system’s ability to move heat, which causes longer run times, cooler supply air, and sometimes ice on the outdoor coil as pressures drop. Hissing noises or oily residue near line sets are classic signs of a leak. Because refrigerant handling is regulated and can damage the compressor if ignored, homeowners should not attempt to recharge systems themselves. Instead, limit runtime to reduce stress, note symptoms, and schedule certified leak detection and repair. Proper leak repair and recharge restore pressures and protect the compressor, bringing back comfort and efficiency.

Spotting refrigerant symptoms early helps technicians focus on the outdoor coil and defrost behavior during their inspection.

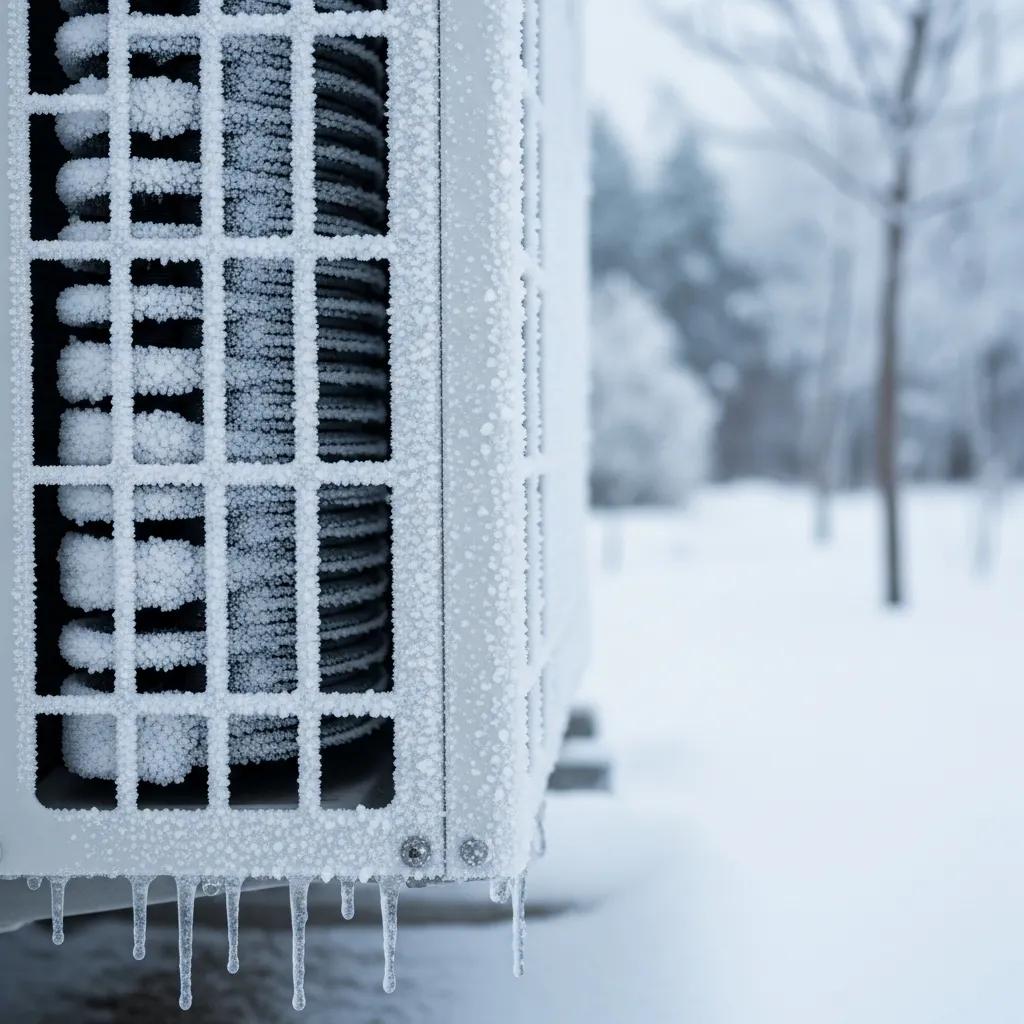

How Do I Fix a Heat Pump That’s Freezing Up? Causes and Safe Steps for NC Homes

Freezing happens when heat exchange is hindered and the outdoor coil temperature drops below freezing, creating frost or solid ice that blocks airflow and reduces heating. Typical causes are dirty indoor filters, a failed defrost cycle, or low refrigerant changing operating pressures. First, focus on safety: power down the system to let it thaw, remove snow and debris from around the unit, and check indoor filters and vents. If ice returns after these actions, have a technician inspect the defrost control, refrigerant level, and blower to prevent repeated damage to the compressor.

Safe thawing and prevention steps to try first:

- Turn off the heat pump at the thermostat and the breaker; let the outdoor unit thaw fully.

- Replace or clean clogged indoor filters to restore airflow over coils.

- Clear leaves and debris from around the outdoor unit and make sure supply and return vents are unobstructed.

- Restart and monitor the unit for re-freezing or strange noises; note whether defrost cycles run.

These steps reduce risk and reveal whether the issue is maintenance-related or needs a professional repair.

| Symptom | Likely Cause / Indicator | Severity |

|---|---|---|

| Light frost that melts each day | Normal defrost activity | Low |

| Heavy, persistent ice on coils | Defrost failure or low refrigerant | High |

| Water pooling near indoor unit | Blocked condensate drain or poor drainage | Medium |

| Unit refreezes after thawing | Possible refrigerant leak or airflow restriction | High |

How Do Dirty Filters and Restricted Airflow Cause Freezing?

Dirty filters and blocked airflow reduce the warm air moving over indoor coils, lowering return temperatures and causing the outdoor coil to run colder than intended — a setup that invites frost. Replace disposable filters monthly during heavy use and clean reusable filters per the manufacturer’s instructions. If airflow remains low after replacing filters, the duct system or blower may need a professional inspection. Keeping proper airflow helps defrost cycles work correctly and prevents repeated freezing.

Fixing airflow issues naturally leads to checking defrost controls, because defrost relies on balanced heat transfer and correct sensor signals.

What Causes Short Cycling and How Do I Fix It?

Short cycling — when the unit repeatedly turns on and off quickly — prevents full compressor cycles, wastes energy, and accelerates wear. It often stems from oversized equipment, dirty coils, or electrical faults that trigger protective cutouts. Poor thermostat placement or aggressive temperature setbacks can also cause frequent starts. Troubleshooting should follow a sequence: check thermostat placement and settings, inspect airflow and coil cleanliness, then move to electrical and refrigerant diagnostics that require a technician. The correct fix may be as simple as a clean filter or as involved as a capacitor replacement or system resizing.

Common causes and homeowner checks:

- Thermostat issues or location causing false calls for heat.

- Dirty coils or restricted airflow forcing short, inefficient runs.

- Electrical faults like failing capacitors or contactors that cut power under load.

These basic checks will often show whether a technician’s amp-draw and component tests are needed.

How Do Electrical Problems and Dirty Coils Cause Short Cycling?

Failing capacitors or contactors can trip protective devices and shut the unit down early, producing rapid on/off cycles. Dirty evaporator or condenser coils reduce heat transfer, which can make the compressor overheat and trigger protective shutdowns after short runs. Homeowners can visually inspect for burnt contacts or oil leaks but should not perform internal electrical tests — measuring amps and capacitor function is a job for a technician. Professional coil cleaning and replacing worn electrical parts restores stable run times and prevents repeat cycles caused by protective trips.

If short cycling continues after cleaning and basic checks, a professional should evaluate system sizing and load characteristics next.

Can an Oversized Heat Pump Cause Short Cycling?

Yes. An oversized system reaches the thermostatsetpoint quickly and then shuts off, causing frequent cycles that prevent proper dehumidification and temperature stability. Symptoms include quick temperature swings, a clammy feeling, and many starts per hour. Fixing oversizing starts with a professional load calculation (Manual J). Options may include replacing the unit with a correctly sized model or adding controls like staging or variable-speed equipment to lengthen run times. Talk to a local HVAC pro to choose the best path for comfort and efficiency.

Resolving oversized equipment is typically a planned upgrade and should be handled by a qualified contractor.

Why Is My Heat Pump Blowing Cold Air in Heat Mode? How to Troubleshoot

If your heat pump blows cold air while in heating mode, something is interrupting the refrigeration cycle or control logic. Common causes are a stuck reversing valve, low refrigerant, incorrect thermostat calls, or the unit temporarily being in defrost mode. First, determine whether the system is in defrost — that’s a normal short period of cold air — or whether it’s a persistent problem. Check thermostat settings, watch the outdoor unit during a cycle, and note sounds, ice, or oil. Replacing a reversing valve or handling refrigerant requires a licensed technician to diagnose and repair safely.

Quick homeowner checks to separate temporary operation from faults:

- Verify the thermostat is set to heat and the setpoint is above room temperature.

- Watch the outdoor unit during a heating cycle to see if the fan and compressor are running.

- Check vents for weak or cold airflow and compare timing to defrost cycles.

- Log unusual noises or persistent cold output to tell the technician.

These observations help decide if it’s safe to wait or time to call for expert diagnostics.

How Does a Faulty Reversing Valve Affect Heating?

The reversing valve redirects refrigerant between heating and cooling modes. If it sticks, the unit can remain in cooling mode and deliver cold air even though the thermostat calls for heat. Symptoms include constant cold supply air in heat mode, clicking sounds near the valve, or inconsistent mode switching. Diagnosing a reversing valve requires a technician to check valve actuation, refrigerant flow, and control voltages; valve replacement involves refrigerant handling and should be done by certified personnel. Repairing or replacing the valve restores proper refrigerant flow and heating function.

If the valve checks out, the technician will then look at refrigerant levels and potential leaks.

When Should I Suspect Low Refrigerant?

Low refrigerant is likely when the system produces weak heat, shows ice on coils, or you hear hissing along refrigerant lines — signs that differ from simple airflow or thermostat problems. Low refrigerant typically causes ongoing poor performance even after filter changes and correct thermostat settings. Because refrigerant work is regulated and requires specialized tools, stop stressing the system, record symptoms, and schedule professional leak detection and recharge. Prompt repair reduces compressor wear and restores capacity before more costly failures occur.

Early detection helps technicians find leaks and return the system to correct pressures, improving efficiency and prolonging life.

When Should I Call a Professional for Heat Pump Repair in Greensboro, Jamestown & High Point?

Call a professional when you see signs of refrigerant leaks, compressor or reversing valve failure, persistent short cycling, electrical issues, or any safety-related symptoms like burning smells or repeated power faults. These problems need licensed technicians for regulated refrigerant handling, high-voltage diagnostics, and component replacement. Choosing a local HVAC provider ensures the technician understands regional climate patterns and common installation details that affect diagnosis. Use the short checklist below to decide whether to call a technician.

When to call a professional — quick decision checklist:

- Yes: Visible oil, hissing sounds, or a suspected refrigerant leak.

- Yes: Repeated short cycling or clicking without sustained compressor runs.

- Yes: Burning smells, breakers that trip repeatedly, or exposed wiring.

- No: Thermostat misconfiguration, simple filter swaps, or snow/debris blocking the outdoor unit.

These rules help you keep DIY work safe and leave complex, hazardous tasks to licensed professionals who follow code. Technicians also provide system-level guidance, such as load calculations and right-sizing, to prevent recurring problems and improve long-term comfort.

How Repair Solutions Inc. Can Help with Heat Pump Repairs

Repair Solutions Inc. offers local HVAC service across Greensboro, Jamestown, High Point, and nearby areas. Our technicians handle diagnostics, refrigerant leak detection, electrical repairs, defrost system service, and component replacements for heat pumps. We use professional testing for refrigerant pressures, compressor health, and electrical integrity so you move from symptom spotting to lasting fixes. If basic checks don’t restore normal operation, schedule a diagnostic visit — we’ll provide safe, code-compliant repairs and maintenance recommendations shaped by local climate and system history.

If a DIY check doesn’t resolve the issue, contacting a trusted local team gets you back to comfortable, efficient operation faster.

How Regular Maintenance Prevents Common Heat Pump Problems: Essential Tips for Greensboro Homeowners

Regular maintenance keeps heat pumps efficient and prevents many common failures by maintaining clean airflow, correct refrigerant charge, and secure electrical connections. Seasonal tune-ups cut the chance of emergency breakdowns and lower operating costs. Inspections in spring and fall let technicians check defrost cycles, verify thermostat calibration, clean coils, and test capacitors and contactors before peak loads arrive. Homeowners should pair professional service with routine filter changes, keeping outdoor equipment free of debris, and watching for early warning signs like odd noises or reduced airflow. The table below outlines core tasks, how often to do them, and the direct benefits to efficiency and equipment life.

Maintenance benefits at a glance:

- Higher efficiency from clean coils and correct refrigerant charge.

- Fewer emergency repairs by catching wear on capacitors, motors, and controls early.

- More consistent comfort thanks to calibrated thermostats and balanced airflow.

These routine actions lower the risk of freezing, short cycling, and compressor stress and make it easier to plan replacements when equipment nears end-of-life.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Filter inspection / replacement | Monthly during heavy use | Restores airflow; reduces icing and short cycling |

| Coil cleaning (indoor/outdoor) | Annually | Improves heat transfer and efficiency |

| Refrigerant check & leak test | Annually or when symptoms appear | Ensures correct charge; prevents compressor damage |

| Electrical component inspection | Annually | Finds failing capacitors/contactors before they fail |

Following this maintenance plan stabilizes performance, reduces energy costs, and extends equipment life by addressing the main failure modes described earlier.

Key Maintenance Tasks to Keep a Heat Pump Running Efficiently

Homeowners can help by replacing filters regularly, removing debris around outdoor units, and keeping supply and return vents clear — these simple actions preserve designed airflow and reduce coil stress. Schedule technician-level tasks annually: refrigerant leak checks, electrical inspections, coil cleaning, and defrost control testing. Keep a service log of each visit and any issues observed — that record helps technicians make informed recommendations and supports warranty claims. Combining homeowner care with yearly professional tune-ups keeps systems efficient and reduces emergency repairs.

Consistent maintenance also supports reliable heating during colder months in the Greensboro area.

Conclusion

Knowing the common heat pump problems and what to check first gives Greensboro-area homeowners the confidence to address small issues and avoid bigger failures. Follow the troubleshooting steps here for safe, practical action — and when problems go beyond basic checks, schedule a professional inspection. If you’d like help, explore our services to keep your heat pump running reliably and efficiently year-round.